In the world of networking, understanding your materials is crucial. Copper Clad Aluminum (CCA) cables, a type of network cable, existing due to their lower cost. But what exactly is a CCA cable? Essentially, it’s an aluminum cable coated with copper, often used in CAT6 and UTP applications. Despite their widespread use, there’s a lot of confusion surrounding CCA cables, their meaning, and their role in networking.

This article aims to demystify CCA cables, providing you with the knowledge you need to make informed decisions about your networking needs.

Understanding CCA Cables

What Is CCA cable?

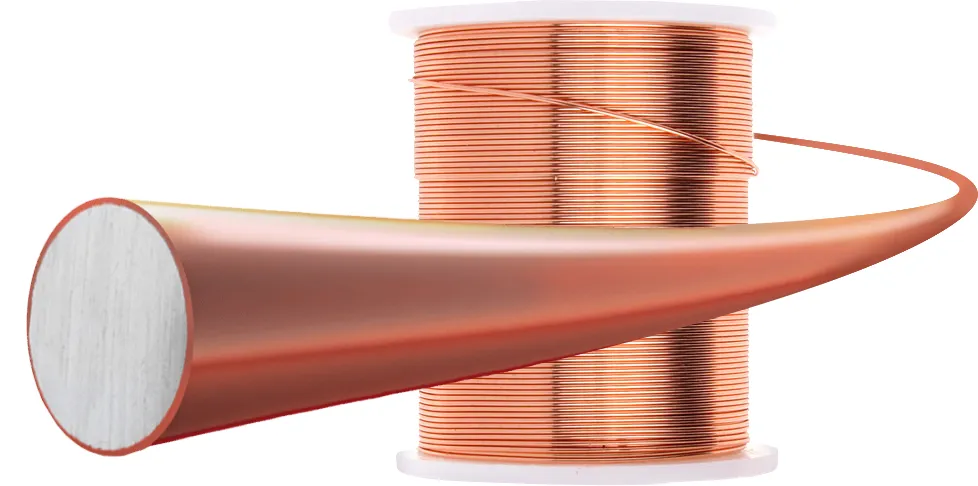

Copper Clad Aluminum (CCA) cables are a unique type of networking cable that combines the properties of both copper and aluminum. At its core, a CCA cable is essentially an aluminum wire that’s coated with a layer of copper. This innovative design leverages the conductivity of copper and the lightweight nature of aluminum, offering a cost-effective solution for various networking applications.

However, it’s crucial to understand the specific characteristics, advantages, and potential limitations of CCA cables to ensure they’re the right fit for your networking needs.

CCA Cables in Electronics

In the realm of electronics, Copper Clad Aluminum (CCA) cables have carved a niche for themselves due to their unique properties. These cables, with their aluminum core and copper coating, are often used in electronic components where weight and cost considerations are paramount. The copper layer ensures excellent conductivity, while the aluminum core keeps the cable lightweight and cost-effective.

However, it’s essential to understand the specific applications and potential limitations of CCA cables in electronic elements to make informed decisions in your electronic design and assembly processes.

CCA Cables in Ethernet Networking

The networking industry is witnessing a surge in the use of Copper Clad Aluminum (CCA) cables, alongside other non-standard conductors, posing as Category-rated cables. While these cables may appear to function like standard cables, their use can lead to significant network issues and potential safety hazards.

Counterfeit or non-standard cabling is not a new issue in the industry. Despite the problems they pose, these cables persist in the market, largely due to their lower cost, making them an attractive option for companies seeking inexpensive networking solutions.

Identifying these non-standard products, including CCA cables, has proven challenging. In response to this ongoing issue, new identification methods are being developed. Testing solutions from companies like Fluke Networks show promise in accurately identifying non-standard cable products. While these solutions can’t instantly identify counterfeit cables, efforts are underway to make it easier for organizations to spot these less-than-standards-compliant products, ensuring network integrity and safety.

CCA Cables vs. Copper Cables

In the world of Ethernet data cabling, Copper Clad Aluminum (CCA) cables often appear as an attractive, cost-effective alternative to solid copper cables. Marketed as meeting the performance requirements of Category 5e or Category 6 networks, and even boasting safety certifications, CCA cables may seem like a good deal. However, it’s crucial to understand the fundamental differences between CCA and copper cables before making a decision.

A key distinction is that CCA cables are not approved for Ethernet networking by any regulatory body. Despite claims of compliance, only stranded or solid copper conductor cables are officially approved for Ethernet data cabling. The National Electric Code (NEC) prohibits the use of CCA Ethernet cable in commercial structures due to safety concerns. Therefore, installations using CCA are considered illegal, and any supposed regulatory approvals are invalid.

CCA cables, while similar in appearance to solid or stranded copper cables, differ in their conductor wire construction. A CCA cable conductor is aluminum coated with copper. This construction leads to several implications:

Despite these issues, some cable resellers market their CCA cables as superior alternatives, claiming more copper plating and dismissing the problems outlined above. These claims are misleading and false. In fact, a browse through any reputable Ethernet data cable source will reveal no CCA cables for sale.

So, how can you ensure you’re getting the quality you deserve? Be wary of deals that sound too good to be true. Purchase from known and reputable sources that manufacture using bare copper conductors. Avoid resellers or manufacturers selling CCA cables, as they’re not suitable for any application. If you suspect you’ve purchased CCA cable, you can strip back the conductor coating and scrape at the copper to see if it exposes aluminum. During installation, if the conductors break when removing kinks, stop and evaluate.

While CCA cables have valid and approved uses in certain electrical applications and voice coils in speakers, they’re not suitable for Ethernet data cabling. Understanding the differences between CCA and copper cables, including patch cords, is essential when choosing the right cable for your application.

The Role of CCA Patch Cords

Could We Use CCA Cat5e and Cat6 patch cord for family ?

Copper Clad Aluminum (CCA) cables, including Cat5e and Cat6 CCA patch cords, are a popular topic in the networking industry. The term “CCA cable” refers to cables that are constructed using aluminum conductors coated with a thin layer of copper. This manufacturing process makes CCA cables, a cheaper alternative to solid copper cables. However, the use of these cables, especially in home networking, comes with several considerations.

Firstly, it’s crucial to understand the meaning of CCA cable in the context of Ethernet networking. Despite their prevalence in the market, CCA cables, including CCA Ethernet cables and CCA network cables, are not approved for Ethernet networking usage by any regulatory body. This means that any claims of compliance with Ethernet standards, such as those made for UTP (Unshielded Twisted Pair) CCA cables, are false. Only solid copper conductor cables are approved for Ethernet data cabling.

The National Electric Code (NEC) also does not provide for the use of CCA Ethernet cable, in structures due to safety issues. Therefore, installations using CCA are technically illegal. If an installer were to run this cabling in a home, the local inspector might take notice and force removal of the installation, regardless of supposed regulatory approvals printed anywhere.

CCA cables, including Cat6 CCA and other CCA Ethernet cables, are brittle and not tolerant of bends. This means they can easily break during installation or even when pulling it off the reel or out of the box. After termination, the end of the aluminum in the CCA wire is exposed to air. Aluminum is very reactive to the environment and will oxidize quickly. This oxidation can create a termination that will eventually fail.

Moreover, CCA cables, including CCA Ethernet and CCA network cables, have much higher electrical resistance than pure copper. This can lead to large amounts of data loss and can eventually lead to slow data speeds. This is particularly prevalent on longer cable runs on or near the 100-meter maximum. All this combined will again lead to a far slower connection for the users of CCA wire-based networks.

In terms of Power Over Ethernet (PoE), CCA cables, are not suitable due to the conductors themselves heating up and potentially starting a fire, or damaging a PoE device on the other end due to the inability to supply enough current.

In conclusion, while Cat6 CCA patch cords and other CCA cables may seem like a cost-effective solution for home networking, they come with significant drawbacks in terms of safety, performance, and legality. It is recommended to use solid copper cables for home networking to ensure a reliable and safe network.

Ensuring Quality and Safety in Your Networking Cables

When it comes to setting up a reliable and safe network, the quality of your Ethernet cables is paramount. However, the market is flooded with various types of cables, including Copper Clad Aluminum (CCA) cables, which can make the selection process challenging. Here are some tips to ensure you’re getting the quality you deserve and play it safe when choosing your networking cables.

Be Skeptical of Too-Good-To-Be-True Deals

While everyone loves a good bargain, a significantly cheaper cable might be a red flag. CCA cables, including CCA Ethernet and CCA network cables, are often marketed as a cost-effective alternative to solid copper cables. However, their lower price comes with significant drawbacks in terms of performance, safety, and compliance with Ethernet standards.

Buy from Reputable Sources

Ensure you purchase your cables from known and reputable manufacturers or resellers. Companies that prioritize quality will manufacture their Ethernet cables using bare copper conductors, ensuring optimal performance and safety. Be wary of resellers or manufacturers selling CCA cables as suitable for Ethernet networking, as these claims are misleading and false.

Check the Weight

CCA cables are much lighter than pure copper cables due to the lighter weight of aluminum. If you notice that the shipping weight of the cable you’re considering is significantly less than that of a known high-quality pure copper cable, this should raise suspicion.

Inspect the Cabl

If you suspect you’ve purchased a CCA cable, you can confirm this by stripping back the coating on the conductors and scraping at the copper. If it exposes aluminum, you’ve got a CCA cable.

Pay Attention During Installation

CCA cables are brittle and not tolerant of bends. If you notice that the conductors break easily when removing kinks or during installation, you should stop and evaluate the quality of the cable.

By following these tips, you can ensure that you’re choosing high-quality, safe, and reliable cables for your networking needs.Stick to solid copper cables for a network you can trust.

Conclusion

In conclusion, Copper Clad Aluminum (CCA) cables, despite their lower cost and widespread use, present significant drawbacks in terms of performance, safety, and regulatory compliance in Ethernet networking. Their brittleness, susceptibility to oxidation, and higher electrical resistance render them a poor choice for Ethernet data cabling and Power Over Ethernet (PoE) applications. Furthermore, their use in such applications is not approved by any regulatory body, making installations using CCA cables technically illegal.

Choosing high-quality, solid copper cables from reputable manufacturers and resellers is strongly recommended for ensuring a reliable, safe, and standards-compliant network. By scrutinizing cable deals that seem too good to be true, verifying the weight of the cable, inspecting the cable for aluminum, and observing the behavior of the cable during installation, users can avoid the pitfalls associated with CCA cables. With informed choices, we can ensure network integrity, safety, and optimal performance.