For many companies, outgoing goods inspections are becoming a thing that is not so serious. Even many companies have no quality control staff. These all are not accepted by today’s market. As for the reason, you know all.

However, we all hope our goods are pretty good enough to get our customers praise, but not complaints or sharing the bad information with their friends. Then the Outdoing inspection is becoming more and more important in order to make sure our goods are perfect.

The importance of Inspection

You should know the benefits of inspection, it will provide numerous advantages. Defective goods result in extra costs and expenditure of time for both the customer and the seller. But after the inspection to make sure suppliers deliver their goods in perfect condition. Only a great inspection provides certainty about the quality of the goods and minimizes the risk of a defective delivery or complaint.

If faults are discovered in the inspection, you may immediately initiate complaints to the suppliers. Telling them the corrective actions and follow-up to ensure our goods are in the best condition. And ask the factory to re-work the products.

Now let’s see our specific inspection steps as follows,

Inspection procedure

Appearance scrutiny

1. Checking the general appearance of the goods Cartons, to be certain if there are damages to them. And the Cartons’ shipping Marks, if there are faults, unclear printings and wrong information.

2. Random sampling of 1/10 of the total goods Cartons, open the box to inspect the product packaging (inner packaging: box or packaging bag). Whether the inner packer is intact and without damage, whether the label is clear and the information is correct.

3. Open the product package (inner package), take out the product. To observe the appearance of the product. Ethernet cable-self (color and logo), printing marks on the cable surface (clear and correct). Both ends of the Plugs are intact and undamaged. Whether the Press tongue piece and press piece into a straight line, without huge deviation.

4. Observe whether the wiring mode of the crystal head meets the standard of the particular ethernet cable.

Appearance testing

1. Use Tapeline to measure the length of products, whether the length is correct and in line with the Printing length on the cable surface.

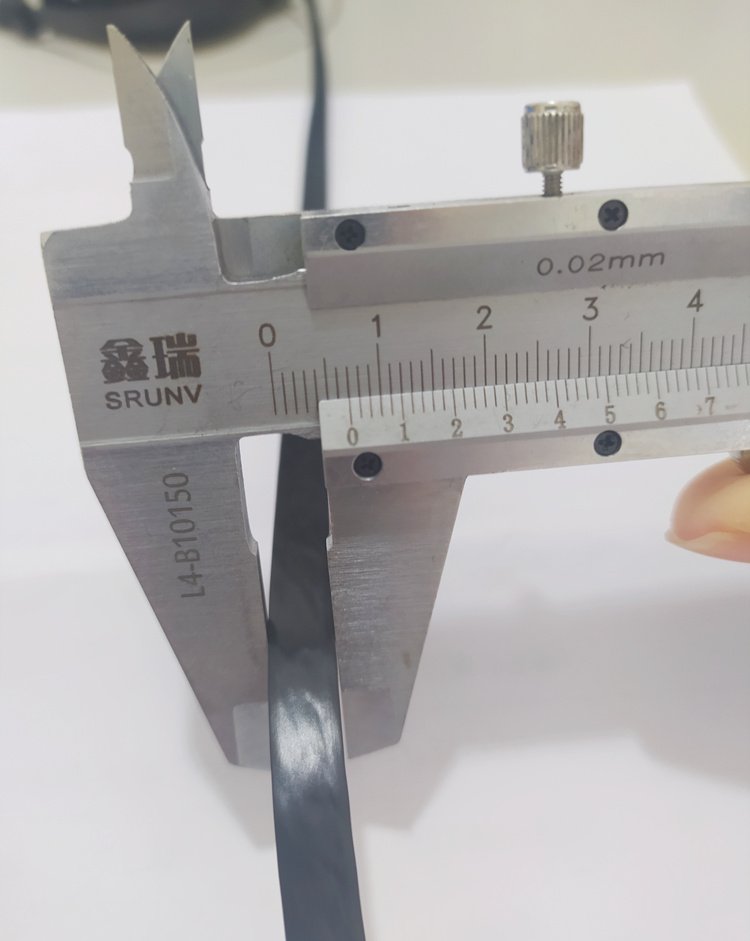

2. Use vernier caliper to test the width and thickness of cable, whether these are conform to the purtacular ethernet cable.

Connection and performance Testing

1. Use the Network tester to check the connection of the cable, if without short circuit or abnormal communication.

2. Use Fluke network cable tester to test the performance of the cable, if it may meet the standard of the Fluke tester.

Popularize knowledge: So what is the fluke test?

The fluke testing is for checking the cable performance if it can meet the particular cable type (cat5e, cat6, cat6a ot cat8 etc.). Including cable length, meters, resistance (ohms), insertion loss margin (dB), frequency (MHz), and prop and so on.

Internal structure

1. Dissect cable to see whether the structure meets the standard of particular cable category..

2. Dissected the core wire and tested the diameter of copper inside with a Micrometer. Compliance with the quotation is to the customer’s specific wire rules.

Conclusione

As we talked at the beginning, all of us expect our products to be pretty good enough to get our customers praise and share with their friends. But do not let the clients disappoint anytime. So you have to enhance your goods quality control. And you must find professional people to make sure of the quality before shipping. It is so important that you need never ever miss that-outgoing inspection.